15 Durable Modern Interior Design Ideas for 2026

Are your units built to look great on day one—and still withstand years of turnovers and heavy use? This guide delivers durable modern interior design ideas for 2026, purpose-built for developers and contractors managing multi-unit projects.

Each idea includes hospitality-grade materials and measurable acceptance criteria, a quick how-to, a common pitfall, and pragmatic procurement notes so you can update specs and RFQs with confidence.

High-traffic surfaces

Corridor LVT and SPC with commercial wear layers

Resilient floors can look upscale while absorbing rolling loads and constant traffic. For multi-unit corridors, prioritize LVT/SPC with a commercial wear layer. Pair dense SPC cores with ceramic bead or aluminum-oxide urethane.

Acceptance criteria should call for a wear layer of at least 20 mil in commercial corridors, with 28–40 mil for heavy traffic. Residual indentation per ASTM F1914 should average ≤0.007 in, and classification to ASTM F3261 should be documented. For standards context, see the performance guidance in AHF Contract’s LVT durability benchmarks.

Procurement notes: Typical MOQs are one 20′ container (≈1,500–2,500 m² per style) with 25–35 days of production for standard designs. Request batch-specific test reports and clear packaging specs.

How-to: Use high-density underlayments where acoustics matter and specify beveled edges for cleaner installs. Pitfall: Under-spec’d 12–16 mil wear layers will show wear lines quickly.

Laminate in units with AC ratings

Modern laminate delivers a crisp look at sensible cost. In living spaces, use AC-rated products and reserve higher classes for amenities. EN 13329 defines abrasion classes; for multi-unit projects, specify AC4 minimum in units and AC5 for heavy-use amenities. The ANSI/NALFA overview of AC ratings explains how these classes relate to wear and impact resistance.

Procurement notes: Confirm warranty scope and grade. Factory schedules vary by line, but laminate programs typically quote fast runs on catalog décors.

How-to: Include moisture-resistant core options near kitchens and entries. Pitfall: Choosing lower AC classes to save a few dollars invites premature wear.

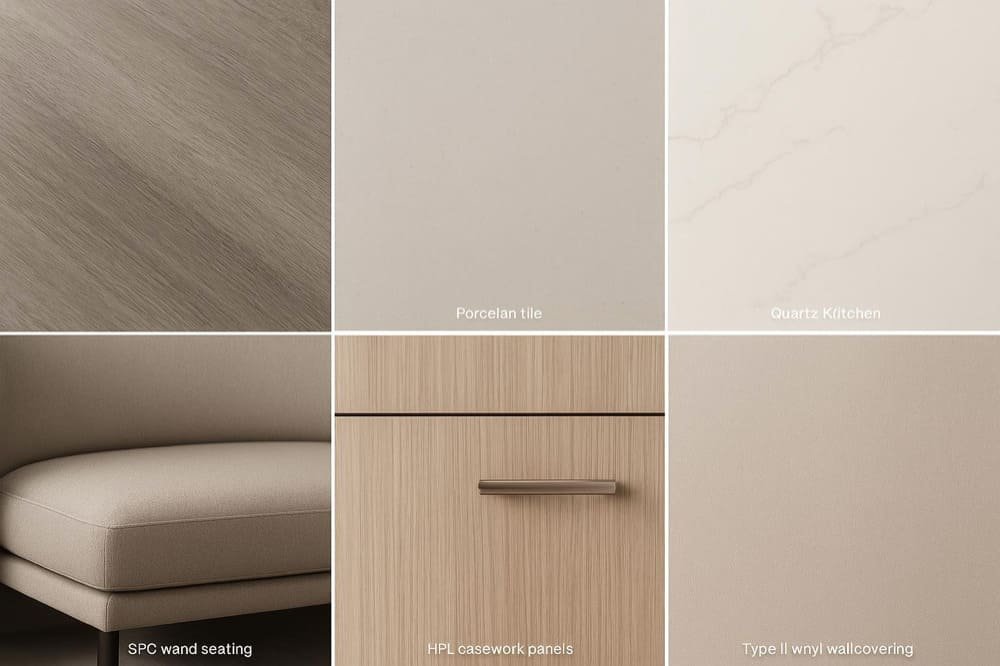

Porcelain tile in wet areas with epoxy grout

Porcelain delivers a sleek, timeless aesthetic and shrugs off water. In showers and laundry rooms, combine porcelain with epoxy grout and confirm slip resistance. For interior floors expected to be walked on when wet, ANSI A326.3 calls for a minimum wet DCOF of 0.42; porcelain absorption should be ≤0.5% per ASTM C373. For reference, see ANSI A326.3 slip-resistance guidance and the ANSI/TCNA overview of ceramic tile standards.

Procurement notes: Tiles often have 15–30 day production windows; epoxy grout is catalog stock. Ask for DCOF and absorption certificates and show movement joints per EJ171.

How-to: Specify bullnose or metal edge trims to protect tile edges. Pitfall: Cementitious grout in high-traffic/wet zones stains and degrades fast.

Engineered wood with tough UV-cured finishes

Engineered wood offers warmth without the movement risks of solid planks. UV-cured urethane or ceramic-reinforced finishes extend life. Target Taber abrasion performance of ≤20–40 mg loss at 1,000 cycles per ASTM D4060 and pencil hardness ≥H–2H per ASTM D3363.

Procurement notes: Lead times run about 3–6 weeks; MOQs are often a 20′ container or ≥700 m² per color for private-label runs.

How-to: Use micro-bevel edges and specify factory-applied finishes for consistency. Pitfall: Site-finished soft coats vary in quality and can burnish prematurely.

Quartz worktops for kitchens and baths

Quartz offers a modern aesthetic and high stain/scratch resistance with easy maintenance. Where code requires surface flame and smoke performance, aim for ASTM E84 Class A (FSI 0–25; SDI ≤450). SWRI’s overview of ASTM E84 Class A thresholds explains the indices.

Procurement notes: Typical MOQs are about 30 slabs per color with 2–4 week production after deposit. Confirm packaging and corner protection.

How-to: Specify integrated backsplashes and radius corners to reduce chipping. Pitfall: Thin edges and cantilevers without support chip and crack under normal use.

Resilient soft-furnishings

Hospitality upholstery with verified abrasion performance

In lounges and lobbies, specify commercial textiles or coated fabrics with validated abrasion resistance. ACT’s voluntary guidelines recommend at least 30,000 Wyzenbeek double rubs or 40,000 Martindale cycles for public spaces, with a caution that ultra-high counts aren’t linear predictors of lifespan. See ACT’s abrasion performance guidance for the disclaimer and thresholds.

Procurement notes: Request ACT icons and lab reports; coated fabrics targeting 50,000 Wyzenbeek are common in hospitality catalogues.

How-to: Choose darker, textured weaves to hide minor scuffs between maintenance cycles. Pitfall: Residential-only textiles pill and wear quickly in common areas.

Type II vinyl wallcoverings for corridors and elevator lobbies

Type II wallcoverings balance modern texture with scrubbability and tear strength for high-traffic walls. Verify ASTM F793 Category V classification, target tear strength around ≥25 lbf and break strength ≥50 lbf per ASTM D751, and check E84 Class A where required. DuPont’s technical sheet on Tedlar wallcoverings shows typical commercial test data.

Procurement notes: Confirm washability ratings and provide cleaning protocols; verify batch color consistency.

How-to: Use encapsulated seams and corner guards at exposed edges. Pitfall: Type I vinyls tear and scuff under luggage and carts.

Anti-graffiti and easy-clean clear coats in vulnerable zones

Elevator cabs, mailrooms, and refuse areas benefit from coatings that resist marker, paint, and grime. Specify products tested to ASTM D6578 with high removal ratings (near 10) using mild cleaners and no visible substrate damage. KTA Tator’s overview of graffiti-resistant coatings testing explains ratings and media.

Procurement notes: Request D6578 test summaries; specify compatible cleaners for janitorial teams.

How-to: Apply two-coat systems over sealed substrates and mock-up removal testing before rollout. Pitfall: Over-stiff films can crack; ensure flexibility and substrate compatibility.

Acoustic assemblies that reduce complaints

Acoustic comfort drives resident satisfaction. Build assemblies that exceed code minimums. Typical code minimums target STC and IIC ≥50 in lab or ≥45 in field; many projects aim for 55–60 to cut complaints. The Construction Specifier primer on multifamily sound control outlines assembly strategies.

Procurement notes: Obtain assembly test reports and underlayment data; coordinate with ceiling systems to avoid flanking paths.

How-to: Seal penetrations rigorously; small gaps can negate performance. Pitfall: Meeting minimums yet ignoring flanking paths leads to noise complaints.

Robust wet-area systems

Waterproofing membranes behind showers and wet walls

Continuous waterproofing protects structure and finishes. Use sheet or liquid membranes tested to modern standards. ANSI A118.10 sets requirements for waterproof membranes, including shear bond and dimensional stability. See TCNA and manufacturer guidance on A118.10 membranes for details.

Procurement notes: Ask for A118.10 compliance documents and installation guides; require installer training certificates.

How-to: Include flood testing protocols and photo documentation before tile. Pitfall: Skipping seams and corners or mixing incompatible products causes slow leaks.

Movement joints in tile fields and perimeters

Movement joints prevent stress buildup and tile failure in large fields or sun-exposed areas. Follow TCNA EJ171 spacing—typically 20–25 ft indoors and tighter grids near sun or wet exposure. See the TCNA FAQ on movement joint placement for recommended spacing.

Procurement notes: Show joint locations on drawings; provide sealant specs and profiles.

How-to: Detail perimeter joints under casework and transitions. Pitfall: Omitting joints leads to tenting and cracks, often months after turnover.

Slip-resistant tiles in kitchens, entries, and laundry

Modern textures and matte finishes can meet slip targets without looking institutional. ANSI A326.3 calls for a wet DCOF of at least 0.42 for level interior floors expected to be walked on when wet. Creative Materials’ overview of updated porcelain tile standards summarizes thresholds and testing.

Procurement notes: Request DCOF test values and finish descriptions; ensure epoxy grout and appropriate trims.

How-to: Use structured finishes in zones prone to spills and combine with cleaning protocols. Pitfall: High-gloss tiles in wet zones become liability magnets.

Durable decorative elements

HPL casework and horizontal surfaces with the right grade

High-pressure laminate maintains a clean modern look on casework while resisting wear. Specify NEMA LD3 HGS/HGL grades for horizontal use and verify Taber wear, impact, and dart resistance. Intertek’s overview of NEMA LD3 testing explains typical performance measures.

Procurement notes: MOQs are often one 20′ container; 15–20 day production is common for standard designs. Request grade and test reports and confirm edge treatments.

How-to: Use post-formed edges or aluminum trims to reduce edge chipping. Pitfall: Using vertical-grade laminate on counters accelerates failure.

Durable paints and clear coats that hold up to cleaning

Walls and woodwork face repeated cleaning cycles. Specify coatings built for scrubbing and abrasion. Seek wall paints with ≥2,000–3,000 scrub cycles to failure per ASTM D2486/D4213 and strong washability per ASTM D3450; for clear coats on woodwork, aim for Taber abrasion ≤20–40 mg at 1,000 cycles and pencil hardness ≥H–2H.

Procurement notes: Request product datasheets with test numbers and GREENGUARD Gold certification where indoor air quality is a priority.

How-to: Use eggshell or matte finishes with burnish resistance in corridors. Pitfall: Cheap paints burnish and stain after a few cleanings; replacement labor erodes savings.

Stainless hardware and robust edge trims

Details drive longevity. Stainless pulls , corner guards, and metal trims protect vulnerable edges while keeping a modern line. Choose brushed stainless and anodized aluminum trims with verified corrosion resistance; ensure fasteners match galvanic requirements.

Procurement notes: Confirm finish consistency and protective packaging; specify radius corners where contact is frequent.

How-to: Add corner guards at elevator lobbies and mailrooms. Pitfall: Painted mild steel chips and rusts in housekeeping cycles.

Quick-spec cheat sheet

| Material or assembly | Measurable metric to call out |

|---|---|

| LVT/SPC corridors | Wear layer ≥20 mil commercial; heavy traffic ≥28–40 mil; F1914 residual indentation ≤0.007 in avg |

| Laminate floors | EN 13329 AC4 units; AC5 amenities |

| Porcelain tile | Wet DCOF ≥0.42; absorption ≤0.5% per ASTM C373; epoxy grout A118.3 |

| Engineered wood | D4060 ≤20–40 mg @1,000 cycles; D3363 ≥H–2H |

| HPL casework | NEMA LD3 HGS/HGL; verify Taber wear and impact |

| Upholstery | ACT: ≥30,000 Wyzenbeek or ≥40,000 Martindale |

| Wallcoverings | ASTM F793 Type II; E84 Class A where required |

| Coatings | D6578 high removal rating |

| Acoustics | STC/IIC ≥50 lab targets |

| IAQ | Prefer GREENGUARD Gold |

On-site QC checklist

- Verify each floor finish against specified wear layer or AC class with manufacturer documents.

- Check tile DCOF values and perform basic slip tests on a wet mock-up; confirm epoxy grout and movement joint placement.

- Inspect casework laminates for correct grade and edge treatments; perform coin-scratch on mock-ups.

- Confirm upholstery abrasion reports and seam durability on samples.

- Review paint and clear coat test values; perform scrub tests on site samples.

- Validate acoustic underlayments and seal penetrations to reduce flanking paths.

Procurement RFQ template highlights

- Performance standards: cite EN 13329, ANSI A326.3/A137.1, NEMA LD3, ASTM E84, ACT abrasion guidance, ANSI A118.3/A118.10, ASTM D6578, ASTM F1914/F3261, ASTM F793.

- Physical specs: thicknesses, wear layers, finish types, dimensions, edge profiles, core/backer types.

- QA/QC: batch test reports, acceptance criteria tables, warranty terms.

- Packaging and labeling: palletization, corner protection, moisture control, lot numbers.

- MOQ and lead time: per color/design; container mix policy; sample timelines.

- Logistics: INCOTERMS, consolidation, port of loading, documentation.

Micro-case comparisons

- Budget corridor floors: 28 mil SPC with ceramic bead finish; lifespan 5–7 years before refinish or replacement in heavy traffic; faster lead times but limited design depth.

- Premium corridor floors: 40 mil SPC or engineered wood with ceramic-reinforced finish; lifespan 8–10 years with routine maintenance; longer lead times but better resident perception and fewer complaints.

Example workflow using a one-stop sourcing partner

Disclosure: ChinaBestBuy is our product.

When you need hospitality-grade SPC at 28–40 mil wear layers and verified ASTM F1914 data, a one-stop partner can consolidate RFQs, vet factory test reports, and coordinate container mixes to hit schedules.

For example, specify F3261 classification, DCOF targets where tiles are included, and GREENGUARD Gold preferences.

Request batch certificates, packaging specs, and photo QC before shipment.

This reduces back-and-forth with multiple vendors while keeping acceptance criteria front and center.

Why these are durable modern interior design ideas

These durable modern interior design ideas prioritize measurable performance and speed-friendly procurement.

Use them to align aesthetics with long-life finishes, predictable lead times, and lower maintenance loads.

If you’re updating specs, start with corridors, wet areas, and casework—then roll the QC checklist into your site walks.