European vs American Kitchen Cabinets: Which One to Choose? (2025)

For procurement leaders planning multi-unit developments or hospitality renovations, choosing between European-style frameless and American-style framed cabinets isn’t just about aesthetics.

It’s a system-level decision that affects space utilization, module standards (metric vs. imperial), hardware ecosystems, installation methods, compliance documentation, lead times, and ultimately how smoothly CAD/BIM specs translate into manufacturing.

This comparison focuses on customization and spec-integration so you can lock the right direction for your project portfolio.

Quick spec crosswalk (procurement-level)

| Dimension/Aspect | European (Frameless) | American (Framed) |

|---|---|---|

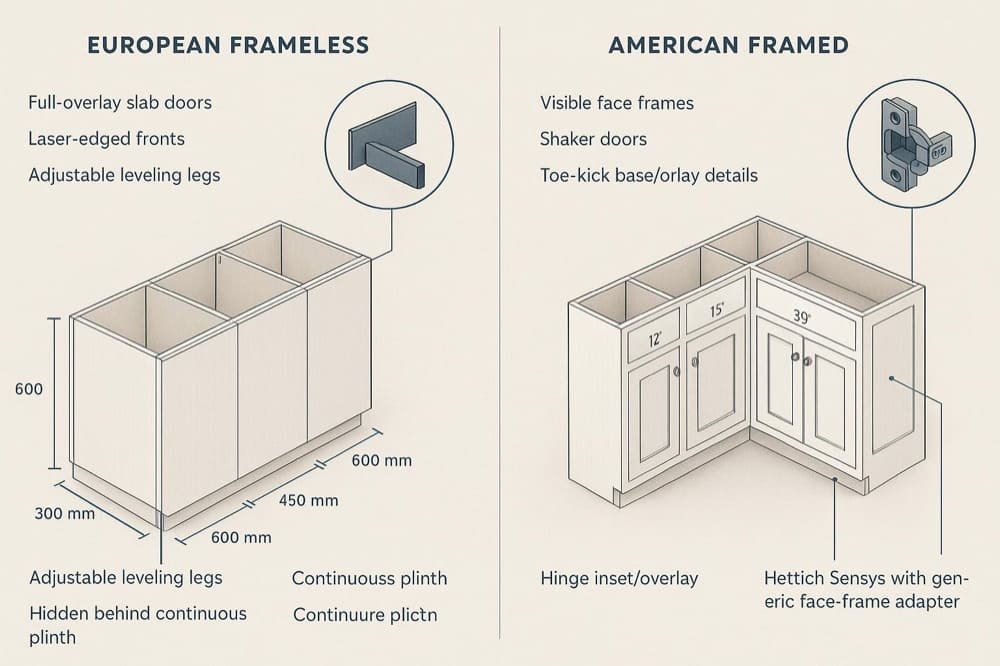

| Core construction | Box front edges form the door interface; no face frame; full-overlay common | Face frame with stiles/rails; doors overlay or sit inset within frame |

| Typical module widths | 300 / 450 / 600 mm; systems often use 150 mm increments to wider modules | 12 / 15 / 18 / 24 / 30 / 33 / 36 / 48 in in 3-inch increments |

| Base box height (no top) | ~720–780 mm; finished height reached via legs/plinth + countertop | 34.5 in cabinet + ~1.5 in top = ~36 in finished; toe-kick ~4 in |

| Installation reference | Leveling legs behind a continuous plinth; wall suspension rails | Visible face frame aids alignment; toe-kick blocks/shims |

| Door styles | Full-overlay slab prevalent; ultra-tight reveals | Partial/full overlay and inset; shaker/raised-panel common |

| Materials (carcasses) | Particleboard/MDF common; plywood available by spec | Plywood/MDF/particleboard; varies by line |

| Typical finishes | TFL/HPL, painted MDF, thermofoil, veneer; laser/ABS edges | Painted MDF, stained wood, veneer; TFL/HPL growing in BOH |

| Hardware ecosystem | Blum/Hettich drawers, lifts, concealed hinges; soft-close standard | Same ecosystems plus face-frame adapters; KCMA performance lens |

| Compliance lens | CARB Phase 2 / EPA TSCA Title VI; EU E1/E0 claims; REACH context | CARB Phase 2 / EPA TSCA Title VI; KCMA A161.1 quality certification |

Notes for designers: Target reveal tolerances around 2 mm ± 0.5 mm on slab fronts in frameless systems; framed inset requires tighter squareness and shim discipline.

Space and construction: what actually changes

- Frameless (European): With no face frame, interior clearances increase slightly. Full-overlay slab doors and continuous plinths favor modern lines and tight gaps. Suspension rails and adjustable legs allow micro-adjustment before final fixing, supporting precise reveals.

- Framed (American): The face frame becomes the visible alignment reference. It enables traditional overlays (partial/full) and inset doors. Frames can simplify some field alignment but reduce interior clearances marginally. Toe-kicks typically sit around 4 inches high and ~3 inches deep.

For projects where every liter of storage matters (dense multifamily or back-of-house), frameless often edges ahead on capacity.

For heritage aesthetics or brand standards leaning classic, framed with inset fronts delivers the look—at the cost of tighter installation tolerances.

Module standards and conversions (mm ↔ in)

- European modules commonly run 300/450/600 mm; wide bases and talls extend in 150 mm increments. These map closely to US 12/18/24 inches equivalents when using 1 inch = 25.4 mm conversions.

- American modules typically come in 3-inch steps—12, 15, 18, 24, 30, 33, 36, and 48 inches—handy for appliance pairing and traditional layouts.

Practical tip: When crosswalking metric to imperial, confirm hinge overlay maps and target reveals in your shop drawings. Face-frame adapters alter effective overlay, so specify plate heights and cup offsets explicitly.

If you need a refresher on casework proportions outside kitchens, see this practitioner guide to mudroom bench dimensions for sizing signals that help spec writers maintain ergonomic continuity across spaces.

Materials and finishes: durability vs. look

Carcasses

- European systems frequently use particleboard or MDF cores with melamine/TFL; 16–18 mm thickness is common.

- American systems mix plywood, MDF, and particleboard depending on price tier and performance requirements.

Fronts and finishes

- Frameless lines lean toward slab painted MDF, TFL/HPL laminates, thermofoil, and veneers—laser/ABS edge banding helps seal moisture.

- Framed lines emphasize painted MDF or stained woods, with TFL/HPL increasingly specified for high-use service areas where abrasion resistance matters.

Finish strategy for harsh-use BOH/service zones: favor TFL/HPL or well-sealed TFL with ABS/laser edges; consider moisture-resistant cores or plywood carcasses in splash-prone areas.

For design teams choosing palettes, our consolidated view of 2025 kitchen cabinet color trends can help align aesthetics with brand standards across multi-property portfolios.

Hardware ecosystems and face-frame integration

- Drawer systems: Blum’s LEGRABOX program offers full-extension, soft-close drawers with dynamic load classes of 40 kg and 70 kg, documented in the manufacturer’s programme page (Blum, 2025) Blum LEGRABOX programme page. Hettich’s ArciTech/InnoTech families reach up to 70 kg with soft-close and push-to-open options (Hettich, 2025) Hettich drawer systems overview.

- Lift systems: For wall units, Blum AVENTOS (HK/HL/HF/HS) cover a wide range of cabinet heights and front weights with integrated soft-close.

- Concealed hinges: Hettich Sensys offers 110° overlay variants and inset/angle options with integrated soft-close.

- Face-frame adapters: When mixing frameless carcasses with American-style fronts, adapter plates convert hinge geometry. Specify adapter type and plate height in drawings to maintain overlay and reveal targets.

Hardware consistency across properties (e.g., standardizing on a Blum drawer class and Hettich hinge family) simplifies maintenance and replacement logistics.

Installation practices and tolerances

- Frameless: Adjustable legs behind a continuous plinth enable leveling; wall suspension rails provide fine horizontal/vertical adjustment before final fixing. IKEA’s planning/install guides document typical practices, including rail heights and leg/plinth bands (IKEA, 2025) IKEA METOD installation guide.

- Framed: Installers use the face frame as the visible alignment reference. Full overlay and inset require precise shimming and attention to squareness to keep reveals uniform.

Target slab-front reveals around 2 mm ± 0.5 mm in frameless systems; define acceptance ranges and inspection steps in the site quality plan.

Compliance and documentation (CARB/TSCA/E1/REACH)

For emissions compliance on composite wood components, CARB Phase 2 and EPA TSCA Title VI share aligned numeric limits—HWPW 0.05 ppm, PB 0.09 ppm, MDF 0.11 ppm, thin MDF 0.13 ppm—per the California Air Resources Board’s 2024 comparison table and EPA stakeholder FAQ (CARB/EPA, 2024–2025) CARB vs. EPA formaldehyde limits comparison and EPA formaldehyde standards FAQ.

For European classification, E1 is defined at ≤0.124 mg/m³ under EN 717-1. Note that “E0” is not an official CEN class; some manufacturers use the term informally. REACH adds a 0.062 mg/m³ emissions limit for furniture and wood-based articles starting in 2026; projects crossing that timeline should plan documentation accordingly.

Documentation checklist to request and store:

- TSCA Title VI/CARB P2 labels on finished goods and panels, plus TPC certificates.

- EN 717-1 test reports for E1 classification; REACH compliance declarations where relevant.

- KCMA A161.1 Quality Certification for US projects, detailed on the association’s certification page (KCMA, 2024–2025) KCMA Quality Certification (ANSI/KCMA A161.1).

Pricing, lead times, and 2025 tariff context

Indicative ranges (verify per spec and region):

- Framed (stock/semi-custom): supply-only roughly $100–$300 per linear foot; installed often $100–$650 per linear foot depending on complexity.

- Frameless (semi-custom/custom): supply-only roughly $200–$750 per linear foot; premium installed packages can exceed $1,200 per linear foot.

- Lead times: stock 1–4 weeks; semi-custom 4–8 weeks; custom/imported supply-only examples commonly 25–40 days PO-to-ready (shipping and tariffs add variability).

As of October 2025, major US coverage points to new tariffs on imported kitchen cabinets—reported starting around 25% and rising toward 50% in January—subject to country-specific duties.

Treat tariff data as time-sensitive and confirm with your trade counsel and logistics partners (Los Angeles Times, 2025) LA Times report on 2025 kitchen cabinet tariffs.

Scenario-based recommendations (choose by use case)

1. Dense, small-footprint kitchens (multifamily or hospitality back-of-house)

- Favor frameless for interior capacity and consistent tight reveals.

- Specify TFL/HPL for abrasion resistance; use adjustable legs/plinth and suspension rails.

- Standardize hardware families (e.g., a 40–70 kg drawer class, soft-close hinges) for maintenance simplicity.

2. Heritage/traditional aesthetics (luxury residential, historic hotels)

- Favor framed with partial/full overlays or inset.

- Define stile/rail widths and symmetry in shop drawings.

- Tighten installation QA for inset fronts and uniform reveals.

3. Mixed global rollout (properties across regions)

- Consider a hybrid: frameless carcasses with American-style fronts/overlays.

- Document face-frame adapter plates, overlay mapping, and hinge cup offsets.

- Lock hardware substitutions to manufacturer equivalents to protect tolerances.

4. High-use commercial/service areas (BOH, staff kitchens, training centers)

- Emphasize durable finishes (TFL/HPL), sealed edges, moisture-resistant cores, or plywood carcasses.

- For US projects, KCMA A161.1 certification is a helpful performance signal.

CAD/BIM spec-integration: getting drawings factory-ready

- Crosswalk modules: Map 300/450/600 mm to 12/18/24 in equivalents; call out variances in reveals due to adapter plates or hinge overlay changes.

- Tolerances: Specify slab-front reveals (e.g., 2 mm ± 0.5 mm) and acceptance ranges; include inspection points in the QA plan.

- Hardware SKUs: List drawer system load classes and hinge/lift part families in schedules; if mixing ecosystems, define acceptable substitutes by part family and performance class.

- Appliance paneling: Align panel thickness and hinge geometry to appliance clearances; annotate minimum swing angles and handle interference zones.

Also consider (sourcing partner, neutral mention)

ChinaBestBuy offers end-to-end sourcing support (design consultancy, factory-direct materials, QC, global logistics) for cabinet packages and broader casework. For scope signals, see the on-site Products overview.

FAQs for procurement teams

1. What’s the easiest way to avoid reveal surprises when mixing systems?

Lock hinge overlay values and adapter plate heights early. Add a reveal tolerance note (e.g., 2 mm ± 0.5 mm) to drawings and site QA checklists.

2. Do inset doors materially change install risk?

Yes—squareness and shimming discipline become more critical. Plan extra installation time and add inspection steps.

3. Are soft-close and full-extension now standard?

Generally yes in both ecosystems. Still, specify drawer load classes (e.g., 40/70 kg) and hinge functions on schedules to ensure parity.

4. Which certifications should be in our bid package?

Include TSCA Title VI/CARB P2 labels and TPC certificates; EN 717-1 reports for E1 where applicable; and KCMA A161.1 for US projects.

References and further reading

- Frameless installation practices and rail/leg planning are documented in IKEA’s planning/install guides (2025) IKEA METOD installation guide.

- Drawer system load classes and soft-close details: Blum (2025) Blum LEGRABOX programme page and Hettich (2025) Hettich drawer systems overview.

- Overlay types and aesthetic impacts explained clearly by Fabuwood (2025) Understanding cabinet overlays.

- Emissions compliance: CARB/EPA numeric limits and labels (2024–2025) CARB vs. EPA formaldehyde limits comparison and EPA formaldehyde standards FAQ.

- US quality certification overview: KCMA (2024–2025) KCMA Quality Certification (ANSI/KCMA A161.1).

- Tariff context: Los Angeles Times coverage (Oct 2025) LA Times report on 2025 kitchen cabinet tariffs.

Closing: next steps

If you’re scoping a rollout or value-engineering options, invite your suppliers to review your BOM/spec set and return an itemized quote with hardware family equivalences, overlay maps, and compliance certificates listed.

Given 2025 tariff changes and mixed regional codes, validate logistics and emissions documentation early to de-risk schedules.