Rough Opening for a 36-Inch Door: Installation Guide

If you’re setting an exterior 36×80 prehung door, this guide walks you through selecting the correct rough opening (RO), framing it accurately, and installing the unit with pro-grade moisture management and verification checks. It’s written for site carpenters, foremen/GCs, and advanced DIYers working in North American framing.

- Difficulty: Intermediate (carpentry + flashing fundamentals)

- Time: 2–4 hours for a pro; 1 day for DIY including flashing and finish checks

- Applies to: Exterior prehung 36×80 single doors with threshold/sill; brief notes for interior and masonry openings

Quick answer: typical RO for a 36×80 exterior prehung door

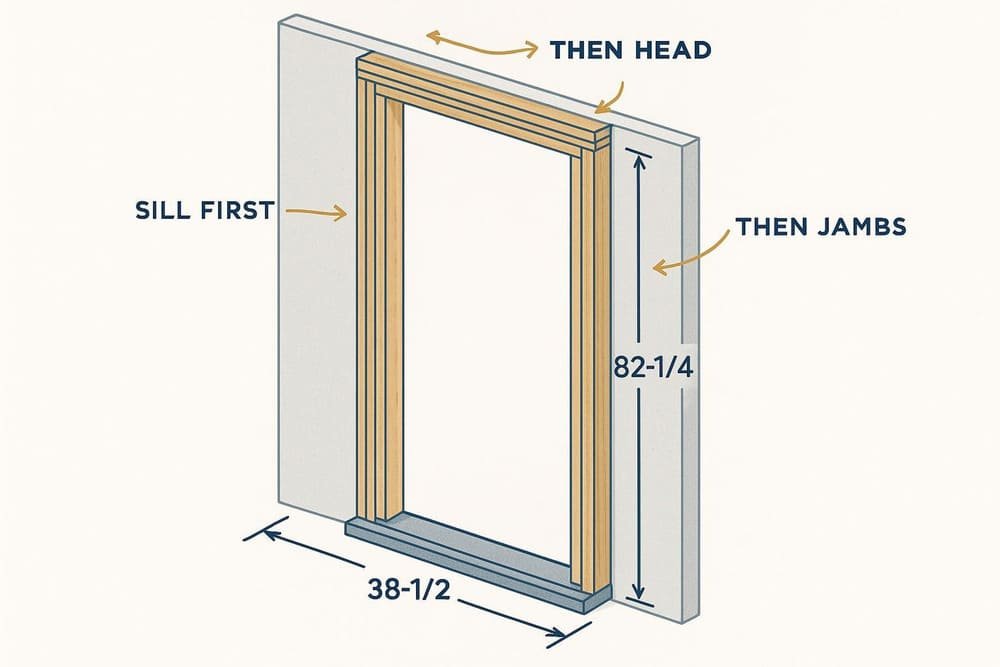

- Most projects land on roughly 38-1/2 in (W) × 82-1/4 in (H) for a 36×80 prehung, which aligns with trade/manufacturer-style guidance and retail listings (e.g., a common 36×80 prehung frame O.D. is about 37-1/2 × 81-1/2, leaving ~1/2 in total side shim and ~3/4 in head clearance) as reflected in the Therma-Tru Benchmark 36×80 listing at Lowe’s (actual 37.5 × 81.5) and the Home Depot measuring guide for doors (2024).

- The practical band most installers use is 38″–38-1/2″ wide and 82″–82-1/2″ high, adjusted by your actual frame size, shim needs, sill pan type, and finished-floor build-up, consistent with ranges summarized in DoorDesignLab’s rough opening guide.

Important: Always verify the final RO against the specific door unit’s submittal (outside-of-jamb dimensions) and your moisture/detail stack.

How to choose 38″, 38-1/4″, or 38-1/2″ (and 82″, 82-1/4″, or 82-1/2″)

- Start from your unit’s outside-of-jamb (O.D.) frame size (e.g., ~37-1/2″ × ~81-1/2″). Many listings publish this; see the Lowe’s example above with 37.5″ × 81.5″ O.D.

- Add adjustment allowances:

- Side shim space: about 1/4″ per side (≈1/2″ total) for plumb/square adjustment and foam/backer rod. This is standard practice echoed in retail/manufacturer instructions like the Lowe’s install PDF stating RO > unit size to allow shimming (2023).

- Head clearance: 1/4″–3/4″ depending on sill pan type (formed vs liquid-applied), membrane layers, and finished-floor build-up.

- Choose toward the larger end (e.g., 38-1/2″ × 82-1/4″ to 82-1/2″) when:

- You’ll use a formed sill pan or layered membranes adding height.

- You plan backer rod and low-expansion foam.

- Field conditions aren’t perfectly true and you want adjustment room.

- Choose toward the tighter end (e.g., 38″ × 82″) when:

- The frame O.D. is on the larger side and the opening is very true.

- You’re minimizing trim gaps and not stacking multiple sill membranes.

- For interior prehung doors (no threshold/pan), 36×80 commonly frames at ~38″ × ~82″—but still confirm the unit O.D. Note that jamb depth affects wall finish alignment, not RO width/height, as clarified in Masonite’s measuring guide.

Tools and materials (non-negotiables)

- Weatherproofing and sealants

- Sill pan (formed metal/plastic) or liquid-applied pan system

- Flexible self-adhered flashing tape and compatible sealant

- WRB integration materials

- Shimming and insulation

- Composite shims; 1/8″ reveal spacers; closed-cell backer rod

- Low-expansion/low-pressure window & door foam (apply in lifts)

- Fastening

- Corrosion-resistant structural screws; long hinge screws (#8–#10, 2-1/2″–3″)

- For masonry: appropriate masonry anchors; e.g., Pella shows 3/16″ masonry fasteners in their entry-door instructions (see Pella installation booklet)

- Layout and verification

- Tape measure; 6′ level or laser; framing square; plumb bob

- Temporary spreaders; story stick; oscillating tool; drill/driver; utility knife; pry bar; hammer

Pro tip: Pre-shim the hinge side at hinge positions before lifting the unit. This comes directly from manufacturer-style guidance like Therma-Tru’s installation knowledge base (2024).

Before you start: measure, plan, and check codes

- Measure your door unit’s O.D. frame size. Do not rely on nominal 36×80 alone. The Lowe’s example cited shows 37.5″ × 81.5″ actual frame O.D. for a 36×80 prehung.

- Plan the sill stack: formed pan or liquid-applied, membrane layers, and finished-floor build-up (tile/wood). More layers → more head clearance.

- Moisture sequencing: Follow “sill → jambs → head” and integrate with the WRB in shingle fashion per ASTM E2112-23 standard practice and the U.S. DOE Building America Solution Center.

- ADA/egress: New ADA thresholds are limited to 1/2″ max height (with bevel rules), and many occupancies require ≥32″ clear width; verify your code set. See U.S. Access Board §404.2.5 thresholds (2024) and ICC IBC 2024 portal for egress widths.

Safety: Wear eye/hand protection, watch sharp metal flashing edges, and verify any electrical/plumbing near the opening before cutting.

Step-by-step installation

1) Verify unit details and site constraints

- Confirm handing/swing, hardware prep, and threshold type. Check the frame O.D. dimension on the submittal.

- Confirm clear opening needs (e.g., ADA 32″ minimum clear) and swing clearance with adjacent walls.

Checkpoints

- Door slab matches plan (handing/swing). Frame O.D. measured. Code constraints identified.

Pitfalls

- Assuming 38″ × 82″ works for all 36×80 units. Always validate against your door’s O.D.

2) Calculate the rough opening

- RO width = frame O.D. width + ~1/2″ total for shims.

- RO height = frame O.D. height + 1/4″–3/4″ for sill pan/floor build-up and adjustment.

Why it matters

- These allowances give you control to plumb, square, and insulate without bowing the jambs. Retail/manufacturer references recommend RO larger than the unit to allow shimming, such as the Lowe’s instruction (2023).

3) Frame the opening

- Install king and jack studs; set a level header. Target your chosen RO (e.g., 38-1/2″ × 82-1/4″).

- Keep studs straight; plane or shim as needed. Confirm sill is level.

Checkpoints

- Stud-to-stud width and subfloor-to-header height within ±1/8″ of target.

- Sill level and straight; hinge-side stud plumb.

4) Prep the opening: sill pan and flashing

- Dry-fit the sill pan. Ensure slope to exterior and a back dam or sealant dam per detail.

- Apply self-adhered flashing at the sill, lapping up jambs 2–6″. Then flash jambs, then head, all shingle fashion, integrated with WRB per ASTM E2112-23 and the DOE Building America guidance.

Pitfalls

- Trapping water by sealing weeps or reversing laps. Keep drainage to the exterior.

5) Dry-fit, pre-shim, and set the unit

- Pre-shim the hinge side at hinge locations (about 10″ from top, at middle hinge, and above bottom hinge). Close and temporarily secure the door slab if possible.

- Set the unit on the pan; center it; use a 6′ level or laser to make the hinge jamb dead plumb.

- Tack fasten at the hinge-side shims.

Pro tip

- Many manufacturers emphasize hinge-side plumb and straight; see Therma-Tru’s install knowledge base (2024).

6) Set reveals and fasten per spec

- Aim for a uniform ~1/8″ reveal between slab and jamb. Pella explicitly targets ~1/8″ in its entry door instructions; see Pella’s block-frame booklet.

- Replace two hinge screws per hinge with longer structural screws into framing (#8–#10, 2-1/2″–3″). This is a common best practice echoed in trade sources like Fine Homebuilding’s prehung door tips (2022).

- Fasten through factory holes or as specified, keeping fasteners at shim points to avoid pulling the jamb out of plane.

- Install head flashing last, lapping over jamb flashing.

- Seal the exterior perimeter joint per manufacturer guidance; don’t seal the sill in a way that traps water.

7) Insulate and air-seal

- Place backer rod in the perimeter gap where sealant will go.

- Apply low-expansion/low-pressure foam in small lifts around the jambs. Avoid overfilling to prevent jamb bowing. Manufacturers caution against high-pressure foams; see Pella installation guidance (2023).

- After cure, trim excess foam and install sealant over backer rod.

Troubleshooting

- If the jamb bows after foaming, cut back the cured foam, reset shims/reveals, and re-foam carefully, consistent with Pella’s cautions in V984527 (2022).

8) Final verification and adjustments

- Check diagonals of the frame; equal diagonals indicate square.

- Confirm even weatherstrip compression, latch/strike engagement, and that the sweep contacts the threshold without excessive drag.

- Confirm threshold elevation meets ADA where applicable; new thresholds generally must not exceed 1/2″ height per U.S. Access Board §404.2.5 (2024).

Interior door notes (brief)

- Interior prehung units typically have no threshold or sill pan. For a 36×80 interior prehung, ~38″ × ~82″ is common, but always verify the frame O.D. before framing. Moisture management is not the same as exterior, but plumb/square and reveal targets still apply.

2×4 vs 2×6 walls: what changes and what doesn’t

- Jamb depth (e.g., 4-9/16″ for 2×4; 6-9/16″ for 2×6) affects alignment with interior/exterior finishes and casing returns, but it does not change RO width/height. This separation of RO from jamb depth is explained in Masonite’s measuring guide.

Masonry/CMU openings (brief)

- Use appropriate masonry anchors through the jamb at shim points. As a reference, Pella’s entry-door instructions call for 3/16″ masonry screws and pre-drilling in concrete/CMU settings; see Pella’s masonry anchor guidance.

- Integrate the sill pan and flashing with adjacent masonry and WRB. Maintain shingle fashion laps and drainage to the exterior.

Troubleshooting: if X, then Y

- RO too tight: Don’t force the unit. Plane high spots, remove interfering drywall or sheathing edges, or widen the RO to target tolerances.

- Threshold too high/low: Reassess the sill pan stack and flooring plan; you may need additional head clearance or to change pan type. Verify ADA threshold limits per U.S. Access Board (2024).

- Hinge-side out of plumb: Back out fasteners, re-shim at hinge locations, confirm with a 6′ level, then refasten. This priority is highlighted in Therma-Tru installation guidance.

- Bowed jamb after foam: Cut out excess foam after cure, reset shims/reveals, re-foam with low-pressure foam in small lifts as advised by Pella (2023).

- Water at sill: Confirm correct pan slope, do not block weeps, and verify flashing order (sill → jambs → head) per ASTM E2112-23 and DOE Building America.

Key takeaways

- Start with the actual frame O.D.—not the nominal size.

- Typical RO targets for a 36×80 exterior prehung are 38–38-1/2 in (W) and 82–82-1/2 in (H); a widely used default is 38-1/2″ × 82-1/4″.

- Pick your head clearance based on sill pan type and finished-floor build-up.

- Flash shingle-fashion: sill → jambs → head.

- Make the hinge side plumb and straight before you chase the reveals.

- Use backer rod + low-expansion foam; avoid bowing the jambs.

Next steps

If you’d like door packages delivered to site with frames, hardware, and weatherproofing kits ready to go—and consolidated logistics—consider requesting a bundled spec and quote from ChinaBestBuy.

We can coordinate prehung units, QC/photo reports, packaging, and global shipping to reduce install errors and simplify your procurement.